Categories

New products

-

Lens Ring Joint Gasket

Lens Ring Joint Gasket, Wholesale Various High Quality Lens Ring Joint Gasket Products from China Lens Ring Joint Gasket Suppliers and Lens Ring Joint Gasket Factory,Importer,Exporter at Kaxite.

-

Double Jacket Gasket

Double Jacket Gasket, Wholesale Various High Quality Double Jacket Gasket Products from China Double Jacket Gasket Suppliers and Double Jacket Gasket Factory,Importer,Exporter at Kaxite.

-

Corrugated Gaskets

Corrugated Gaskets, Wholesale Various High Quality Corrugated Gaskets Products from China Corrugated Gaskets Suppliers and Corrugated Gaskets Factory,Importer,Exporter at Kaxite.

-

PTFE Envelope Gasket

PTFE Envelope Gasket, Wholesale Various High Quality PTFE Envelope Gasket Products from China PTFE Envelope Gasket Suppliers and PTFE Envelope Gasket Factory,Importer,Exporter at Kaxite.

-

Rubber Sheet

Rubber Sheet, Wholesale Various High Quality Rubber Sheet Products from China Rubber Sheet Suppliers and Rubber Sheet Factory,Importer,Exporter at Kaxite.

Molded PTFE Tube

Molded PTFE Tube OD: 30mm to 600mm Length: 10mm to 300mm/pc we have virgin molded ptfe tube, filled molded ptfe tube, fiber glass molded ptfe tube, graphite filled molded ptfe tube, bronze filled molded ptfe tube.

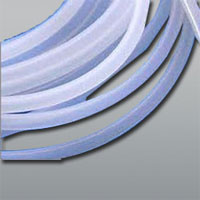

PTFE Tubes

We are the leading supplier of the ptfe tubes. The all manufacturing process is design in such a way that minimizes the cost of the production. Our ptfe tubing is appreciated and favored by the customers for their performance.

It consists of all characteristics of ptfe, which is an ideal raw material among all plastics. It has internally smooth structure, which made it so strong and flexible. It consists anti friction, anti-brokage and anti-blockage characteristic. It's highly resistant to the corrosive chemicals. It also consists of good dielectric strength and good tensile strength.

Advantages

• Smooth inner surface

• Abrasion resistance

• High temperature resistant

• High dielectric strength

• High strength against pressure

• anti-friction

• anti-corrosive

• Flexible.

• Non-contaminating

|

PTFE Tubing & SLEEVES |

||

|

Standard Size: 3mm to 28mm wall thickness: 0.75mm to 2mm Grade: VIRGIN Tem. Range: -200 Deg.C to + 250 Deg.C., good dielectric insulation properties. Tensile Strength: between 2,500-4,000 Density: 2.13-2.24 |

|

Data Sheet

| Property | ASTM test | Value | |

|---|---|---|---|

|

Physical properties |

Specific gravity | D792 | 2.15 |

| Water absorption ( % ) | D570 / 24 hrs 1/3" t | < 0.00 | |

| Mold shrinkage ( cm / cm ) | 0.02 - 0.05 | ||

| Contact angle ( degree ) | Angle to level | 110 | |

|

Thermal properties |

Thermal conductivity (cal/sec/cm2, o /cm ) |

C177 | 6 x 10 - 4 |

| Coefficient of liner thermal expansion(1/oC) | D696 / 23 - 60oC | 10 x 10 - 5 | |

| Melting point (oC ) | 327 | ||

| Melt viscosity ( poise ) | 1011 - 1013 | ||

| (340 -380oC) | |||

| Maximum temperature for continuous use (oC / oF ) | 260 / 500 | ||

|

Mechanical properties |

Tensile strength ( kgf / cm2 ) | D638 / 23oC | 140 - 350 |

| Elongation ( % ) | D638 / 23oC | 200 - 400 | |

| Compression strength ( kgf / cm2) | D695 / 1 % deformation, 25oC | 50 - 60 | |

| Tensile modulus ( kgf / cm2 ) | D638 / 23oC | 4,000 | |

| Flexural modulus ( kgf / cm2 ) | D790 / 23oC | 5,000 - 6,000 | |

| Impact strength ( ft - lb / in ) | D256 / 23oC, Izod | 3 | |

| Hardness (Shore) | Durometer | D50 - D65 | |

| Deformation under load ( % ) | D621 / 100oC, 70 kgf / cm2, 24 hrs | 5 | |

| D621 / 25oC, 140 kgf / cm2, 24 hrs | 7 | ||

| Static friction coefficient | Coated - steel surface | 0.02 | |

|

Electrical properties |

Dielectric constant | D150 / 103Hz | 2.1 |

| D150 / 106 Hz | 2.1 | ||

| Dielectric dissipation factor | D150 / 103 Hz | < 1 x 10 - 5 | |

| Dielectric break down strength ( V / mil ) | D149 / Short time,1/ 8 in | 480 | |

| Volume resistivity( ohm - cm ) | D257 | > 1018 | |

| Chemical resistance | Excellent | ||

| Weather ability | Excellent | ||

| Combustibility ( % ) | D2863 / Oxygen concentration index | > 95 | |